AN INTIMATE LOOK INTO A FASCINATING SOLAR LAB

Copenhagen International School

Photos of Copenhagen International School, covered with revolutionary solar panels, have made the news around the world. Andreas Schüler, the solar energy physicist who was the project leader from day one, has shown us around his laboratory in Lausanne, Switzerland.

If you are looking for the LESO-PB (Solar Energy and Building Physics Laboratory), one of the 350 laboratories of the EPFL (Swiss Federal Institute of Technology in Lausanne), you’ll have to go right into the heart of the campus, (a small city on its own), where almost 14,000 people, including 10,000 students of 150 different nationalities come every day.

The discreet entrance is situated under a footbridge. Who knows how many such labs there are in the world, hidden in narrow campus streets? These little-known places of invention that give birth, after so many late nights at work, to technologies that will change tomorrow’s avenues, airports and cities.

At the end of a windowless corridor, ironically, in a dusky light with no sunshine, Andreas Schüler suddenly appears. He comes up to meet us and, after short presentations with his team of young scientists from all over the world, he is eager to discuss our topic.

On the threshold of his laboratory, he starts by showing us the charts and plans posted all over the wall. He comments in French with a German accent and makes us think of the archetypal figure of a scholar who is keen to communicate with us, simple mortals. His enthusiasm is infectious, he wants to tell and show it all, to enlighten us. In his kind way, he wants us to understand. Obviously, he starts by talking about the major project that has just been completed and that has made us visit him in his scientific den.

Andreas Schüler is a German physicist who graduated from the university of Freiburg im Breisgau (the city of Fraunhofer, a major solar institute). He got his PhD in Basel on the topic of optical and electronical characteristics of nanometric structures called “thin films”. Upon arrival at the EPFL, he joined the LESO-PB, Professor Jean-Louis Scartezzini’s laboratory, dedicated to energy efficiency and the integration of renewable energies into the built environment. He led research which culminated after 12 years, last February, with the inauguration of Copenhagen International School’s new building in Denmark.

The facades being entirely covered with solar panels, a total of 12,000, the building attracted worldwide attention for the EPFL. It is not only the greatest achievement so far by its size, it is also and above all an innovative process, the application of thin films on glass panels, which makes the building so unique: deposited on the glazing of solar panels, these fine nanometric layers control reflected wavelengths of light and therefore the façade’s colour. We are then led into the lab for further explanations.

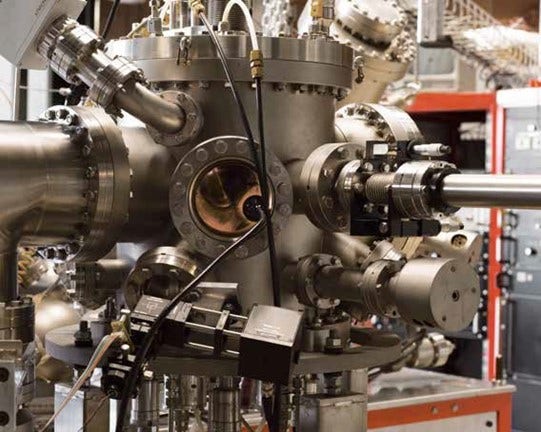

As soon as we step into the room, an impressive object draws all our attention. We discover a striking installation, a sort of a giant engine bristled with tubes, portholes and bolts, connected to a myriad of pumps. Is this thing used for changing dimensions? Or is it a time machine? The answer is yes, for we are in a nanotechnology lab and this machine is used for testing new materials and processes that will be used for tomorrow’s solar panels.

The scientist explains: “The machine is used essentially for the vacuum deposition of thin layers, to test new materials. We use a process called cathode pulverization. There is a target on a water-cooled magnetron. Electric power creates a plasma. In the plasma, there are ions and these ions bombard the target’s atoms that are sputtered. The target’s material is deposited on the substratum, which is a glass sample of 7.5 x 7.5 cm, forming a very thin layer on its surface.” It is this very thin film layer of 10 to 200 nm, sometimes made up of several superimposed layers that determines the solar panel’s colour.

The facades of Copenhagen International School are covered with sea-green panels, aesthetically matching the waters of the Øresund strait, as the institution is standing on its banks. When imagining their buildings, architects can at last choose out of a whole range of colours. Solar panels are actually part of the architectural concept and this is what we call urban integration.

As no pigments are used, light reaching the solar collectors is not absorbed. Even though perceived colours may vary, the primary aim is achieved: “Energy conversion is under control. The Copenhagen building can produce 300 MWh per annum, which is half of the school’s energy consumption.”

Coloured panels developed and tested by the laboratory then went through a successful technology transfer process. SwissINSO, a spin-off of the EPFL, has contacted various glass and (photovoltaic and photothermal) solar panel manufacturers. The coloured glass panels used in Copenhagen were produced by Emirates Insolaire in Dubai. The photovoltaic panels using these glass panels were manufactured by SolarLab. “In the Middle East and in Asia, there are many glass buildings. Moreover, they endorse the creation of joint-ventures. We found the best conditions in Dubai and they had the machines capable of producing what we needed”, meaning 3x6-meter glass panels with a homogeneous thin film, the thickness of which never varies by more than 5 nm, the limit that guarantees the colour.

Chemical, optical and thermal experiments, the laboratory has many more surprises. In an adjoining room, scientists are working on intelligent windows. Finely profiled, they direct light differently depending on the sun’s position and therefore, on the season. In the winter, they will be able to redirect light entering a room, to enhance natural light. In the summer, they will also be capable of focusing part of the sun beams so that they are reflected outside, to limit heat. As one of the scientists inclines the sample to show us the structure, Andreas Schüler is clearly keen on talking about something else.

Led into a small workshop, we discover an apparently ordinary window. Our host, all smiles, tells us about its story. Railway companies wanted to equip their trains with windows containing low-emission layers, to better keep heat inside the carriages. The problem is that these windows impede the use of mobile phones by blocking their waves. The only solution known at the time was to install signal amplifiers to pass the waves through the inside of the trains. Antennae were to be changed every 4 to 8 years, following the evolution of mobile telephones.

“To a person with a hammer, every problem looks like a nail” says our scientist with an enigmatic smile, once the context is introduced, then he explains: “We are thin film specialists, so we approached the problem from our point of view! We proposed the idea of working on electron mobility inside the thin layer of windows. We ended up by finding a new solution: microwave windows.”

Thanks to a new process which laser-grooves thin films, Andreas Schüler, his colleagues and partner engineers have created a window with all the thermal characteristics of low-emission-film windows, but with small “spaces” in their structure, so that telephone waves can pass through. No more signal amplifiers, no more new investments every 4 to 8 years. The trains that have been equipped were successfully tested by Swisscom, the major telephone operator in Switzerland.

The possible implications of this technology are mind blowing. “In the future, buildings will be full of connected devices exchanging data through Wi-Fi and packed with sensors to control light, temperature, detect the presence of people… waves will have to pass through everywhere”. Long working days are ahead for Andreas Schüler’s team, in the silence of his lab. Thermochromic materials, logical devices or electric circuits changing characteristics according to temperature, their drawers are full of projects.

As the sun is setting, Mr Schüler suddenly remembers that he has a project for the evening. A conductor in his laboratory, he is also a volunteer pianist and entertainer for children’s shows, for which he also composes music. Tonight, there’s a rehearsal.

The impressive device for testing new materials

Jing Gong, research assistant and PhD student showing us an intelligent window sample